Livestock Spare Parts Warehouse Solutions

Using AI Unmanned Warehouse Solutions to Achieve Precise Spare Parts Material Management and Improve Production Efficiency

Pain Points in Industrial Safety Material Management

A wide variety of spare parts, traditional management methods are inefficient.

-

Complex Usage Processes

Manual registration takes a long time, affecting production efficiency.

-

Lack of Transparency in Inventory Data

Inventory data updates are not timely, often resulting in material shortages.

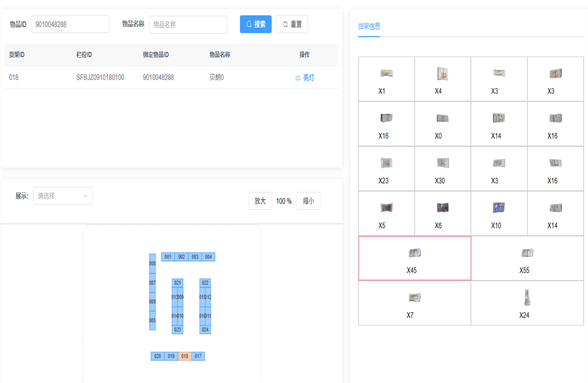

Provide Various Forms of Unmanned Store Products

-

Livestock Equipment Unmanned Warehouse

Livestock Equipment Unmanned WarehouseCapacity: 1,200 Pieces of Equipment

Area: 12㎡

Accommodates 4 People Simultaneously

Location: Equipment Room

-

.jpg) Feed Management Unmanned Warehouse

Feed Management Unmanned WarehouseCapacity: 2,000 Items

Area: 20㎡

Accommodates 5 People Simultaneously

Location: Feed Warehouse

-

Veterinary Supplies Unmanned Warehouse

Veterinary Supplies Unmanned WarehouseCapacity: 700 Items

Area: 8㎡

Accommodates 3 People Simultaneously

Location: Veterinary Room

How AI Unmanned Warehouses Enhance Livestock Production Efficiency

Intelligent Management for More Efficient and Safer Spare Parts Flow

-

Precise Material Management

-

Seamless Usage Process

-

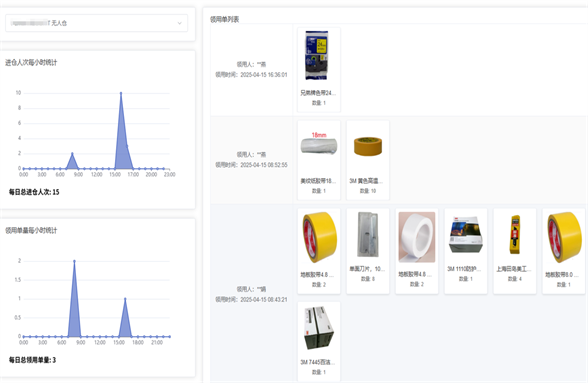

Real-Time Inventory Monitoring

-

Precise Material Management

AI technology records the usage of materials in real-time, ensuring the clear flow of each item.

-

Seamless Usage Process

-

Real-Time Inventory Monitoring

Hear What Our Clients Say

-

The speed of locating spare parts has significantly improved, greatly enhancing production efficiency.

Operations Manager at a Livestock Farm

-

Veterinary supplies management is more standardized, reducing breeding risks.

Veterinarian at a Livestock Farm

(1)-630.jpg)