Industrial Safety Unmanned Warehouse Solutions

Using AI Unmanned Warehouse Solutions to Achieve Efficient Safety Material Usage and Enhance Safety Management

Pain Points in Industrial Safety Material Management

Safety material inventory is opaque, often leading to shortages that affect employee safety.

-

Disorganized Protective Equipment Management

Lack of record-keeping in protective equipment usage, prone to loss or damage, increasing safety risks.

-

Inefficient Tool Usage

Tool usage processes are complicated, often delaying production schedules.

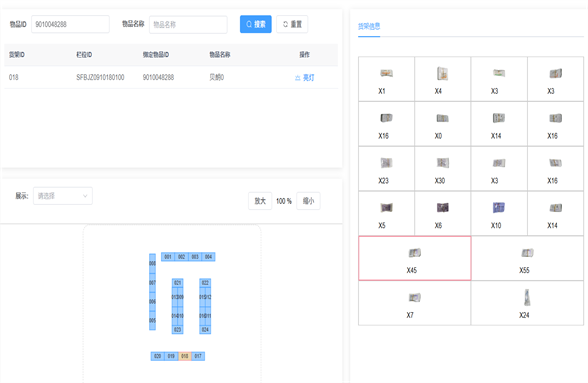

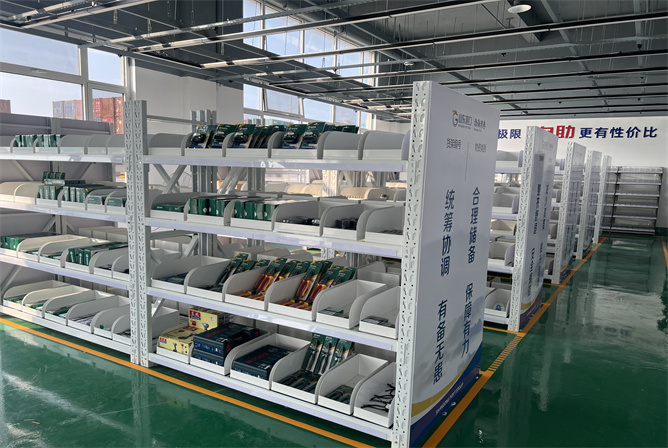

Provide Various Forms of Unmanned Store Products

-

Safety Supplies Unmanned Warehouse

Safety Supplies Unmanned WarehouseCapacity: 1,000 Safety Items

Area: 10㎡

Accommodates 4 People Simultaneously

Location: Workshop

-

Protective Equipment Management Warehouse

Protective Equipment Management WarehouseCapacity: 700 Pieces of Equipment

Area: 8㎡

Accommodates 3 People Simultaneously

Location: Safety Area

-

Tool Usage Unmanned Warehouse

Tool Usage Unmanned WarehouseCapacity: 500 Tools

Area: 6㎡

Accommodates 2 People Simultaneously

Location: Tool Room

-

Emergency Supplies Storage Warehouse

Emergency Supplies Storage WarehouseCapacity: 1,100 Items

Area: 12㎡

Accommodates 4 People Simultaneously

Location: Emergency Area

-

Cleaning Supplies Management Warehouse

Cleaning Supplies Management WarehouseCapacity: 700 Items

Area: 8㎡

Accommodates 3 People Simultaneously

Location: Cleaning Area

How AI Unmanned Warehouses Ensure Industrial Safety

Intelligent Management for More Convenient and Safer Safety Material Usage

-

Grab and Go

-

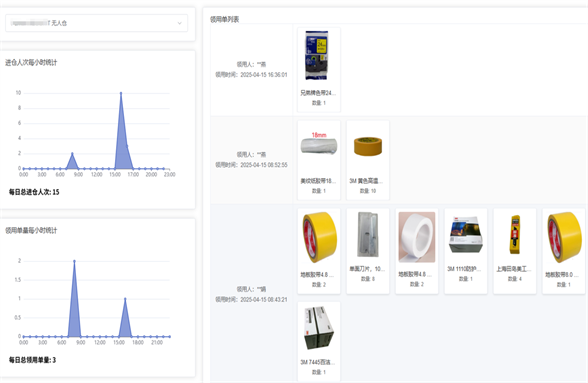

Real-Time Inventory Monitoring

-

Reducing Labor Costs

-

Data Analysis Optimization

-

Grab and Go

Employees do not need to register; the usage process is fully automated, improving efficiency by 10 times.

-

Real-Time Inventory Monitoring

-

Reducing Labor Costs

-

Data Analysis Optimization

Hear What Our Clients Say

-

Unmanned management has saved a significant amount of labor costs, and the boss is very satisfied.

Financial Director at a Factory

-

The data analysis feature helped us optimize our procurement plan, reducing waste.

Purchasing Manager at a Factory