Factory line side unmanned warehouse solution

Through AI unmanned warehouse solutions, accurate management of line materials is achieved to improve production efficiency

The pain points faced by factory line warehouse material management

There are many types of materials at the line, and traditional management methods are inefficient

-

Consumables inventory is not transparent

Consumables inventory data is not updated in a timely manner, and shortages often occur, affecting production progress

-

High tool loss rate

There is no record of tool collection, which is easy to lose and increases procurement costs

Provide various types of unmanned store products

-

Unmanned warehouse for spare parts near the production line

Unmanned warehouse for spare parts near the production lineCapacity: 900 spare parts

Floor space: 10 square meters

Number of people who can borrow at the same time: 3

Placement location: Next to the production line

-

Unmanned warehouse for tool management

Unmanned warehouse for tool managementCapacity: 1,200 cutting tools

Area: 5 square meters

Number of people who can borrow at the same time: 2

Placement location: Tool storage area next to the line

-

.jpg) Unmanned warehouse for consumables

Unmanned warehouse for consumablesCapacity: 1,100 consumables

Floor space: 12 square meters

Number of people who can borrow at the same time: 4 people

Placement location: Next to the production line

-

Safety Equipment Management Warehouse

Safety Equipment Management WarehouseCapacity: 1,000 pieces of equipment

Floor space: 10 square meters

Number of people who can borrow at the same time: 3

Placement location: Safe zone

How AI unmanned warehouses improve factory production efficiency

Intelligent management makes the flow of materials at the line more efficient and safer

-

No-brainer collection process

-

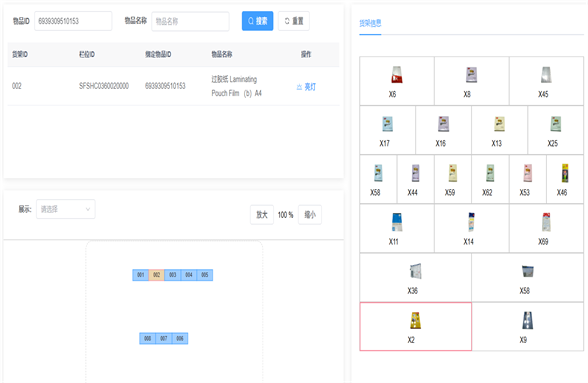

Intelligent Guidance

-

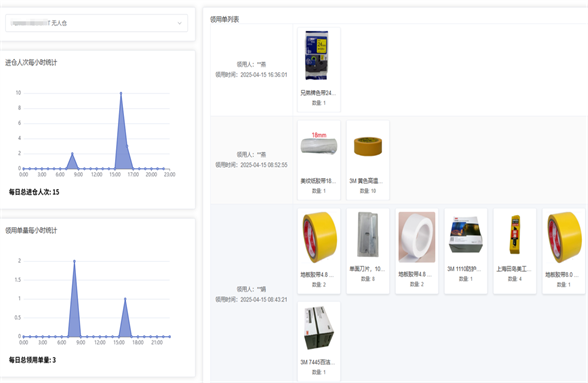

Data analysis to optimize inventory

-

Real-time monitoring of consumables

-

No-brainer collection process

Take it and go, no manual registration required, greatly improving the efficiency of collection

-

Intelligent Guidance

(1).jpg)

AI vision combined with multi-sensor guidance function, spare parts search time is shortened by 50%, and production efficiency is greatly improved

-

Data analysis to optimize inventory

Optimize spare parts and consumables procurement plans and reduce costs through big data analysis

-

Real-time monitoring of consumables

The system updates inventory data in real time to ensure sufficient consumables and worry-free production

Hear what our customers have to say

-

AI-powered unmanned warehouses have increased our material management efficiency several times over and accelerated repair speeds.

Maintenance Supervisor, Power Company

-

Contactless collection is so convenient. I no longer need to use paper records every time I collect materials, which saves a lot of time and prevents errors.

Production Supervisor at a certain factory

-

Data analysis capabilities helped us optimize our procurement plans and reduce waste.

Purchasing manager at a factory